Garage Innovators

This article was later published on Trail4Runner.com on December 13, 2022. All images are owned by the respective individuals.

Have you ever worked on your 4Runner and an idea for a modification popped into your head? Perhaps something that would make your life easier or solve a unique problem? If so, consider yourself a junior member of the inventor’s club. In this article, we want to highlight five members of this club who went one step further and brought their simple yet effective custom 5th Gen 4Runner products to the community.

Taking your idea to the next step might seem formidable, but there’s never been a better time to do so. There are 3D printers available for just a few hundred dollars and almost limitless YouTube videos to soak up whatever sweet knowledge you need. Not only can you order entirely custom-printed circuit boards in as little as 24 hours, but you can also establish an online store reaching basically anyone in just a few clicks (or taps).

These modern tools have made the development of an idea into a product much easier. However, the road is still long and full of hurdles, setbacks, and sometimes even entirely alternative paths. A major theme shared by all of the folks listed in this article is that it’s critical to be resilient during the long process of developing your invention into a viable product.

Your 3D-printed product might perform admirably in Northern California but become brittle in the extreme winters of Canada or warped from the hellfire of summer in Arizona. No matter the issue, you will have to adapt and overcome it while still pushing forward.

This isn’t to say being an inventor is all doom and gloom. Taking an abstract concept in your head and physically forming it into an object another human being will pay you money for is a major milestone. It’s extremely difficult but incredibly rewarding!

To help others that are on this journey, we asked these inventors for any insight and knowledge that they could offer to the next great creator out there.

1. Lab Ops Gear Dash Mount by John

Early version of a 3D printed Labops dashmount

Our first product is a very subtle dashboard mount, which looks incredibly OEM+. This was entirely the goal of the inventor, John, and his company, LabOps Gear, maker of the non-drill dash mount.

He wasn’t really a fan of drilling his dash and the overly wide size of traditional mounts like the ICS Fab or Expedition Essentials but still needed a solution to mount his phone and gadgets. While cleaning his 4Runner one day, he noticed a separate piece of the dashboard trim just in front of the digital clock. After seeing that, he started to fabricate a piece that would fit. About eight versions later the first usable prototype worked surprisingly well.

Through word of mouth, his product became a hot commodity. John bought two more 3D printers to keep up with demand since each mount took about 14 hours to print. Even still, demand continued to grow and John started to explore the possibility of creating an injection-molded model of his mount.

Transitioning from a 3D printed mount to injection molded introduced a variety of engineering issues. John had to learn about injection flow patterns and a variety of other hurdles to overcome. In the end, changing over to an injection molded model was better since it had more structural integrity despite having less width in certain parts of the mount.

Injection molded compared to 3D printed

John, who has a Ph.D. in Biochemistry, is no stranger to the prototyping and engineering process of developing a solution. However, much of the work involved with designing the dashboard mount in CAD software was entirely new to him.

His only regret was not starting with professional CAD software at the beginning. After transitioning from freeware CAD software he had to re-learn all of the fundamentals again, which took a significant amount of time. Professional CAD software is by no means cheap but there might be alternatives available such as education discounts or classes at your local community college that come with a software license.

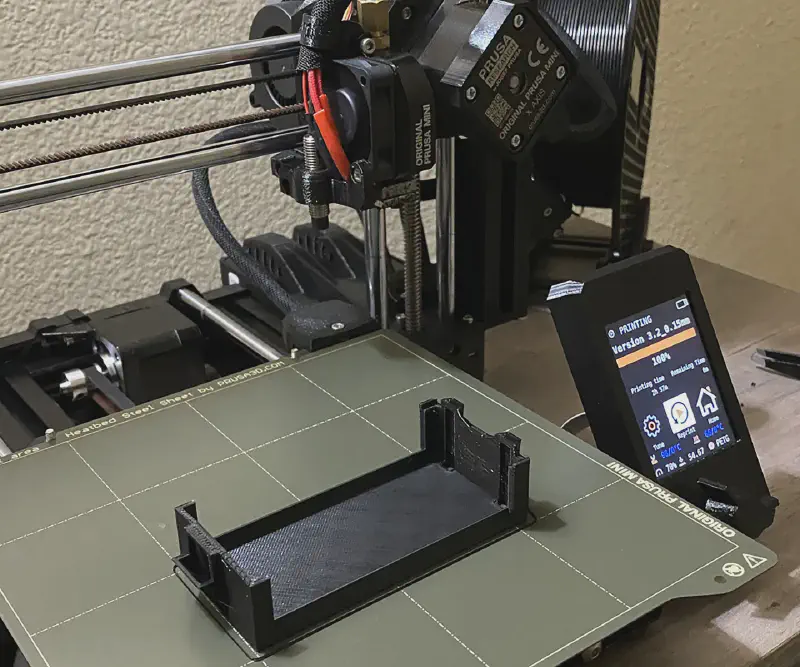

3D printing a prototype

Being a new vendor in the overlanding community has been surprisingly pleasant for John. He shared that there has been a general willingness to accept new products and ideas. In addition, people have been incredibly patient and tolerant of delays while John and LabOps Gear have grown and adapted to the higher product demand; all while transitioning from a 3D printed version to an injection-molded dashboard mount.

John said he attributed this to the innate quality of people who enjoy the outdoors and the camaraderie that goes along with it.

2. Extended Fuse Cover by Minh

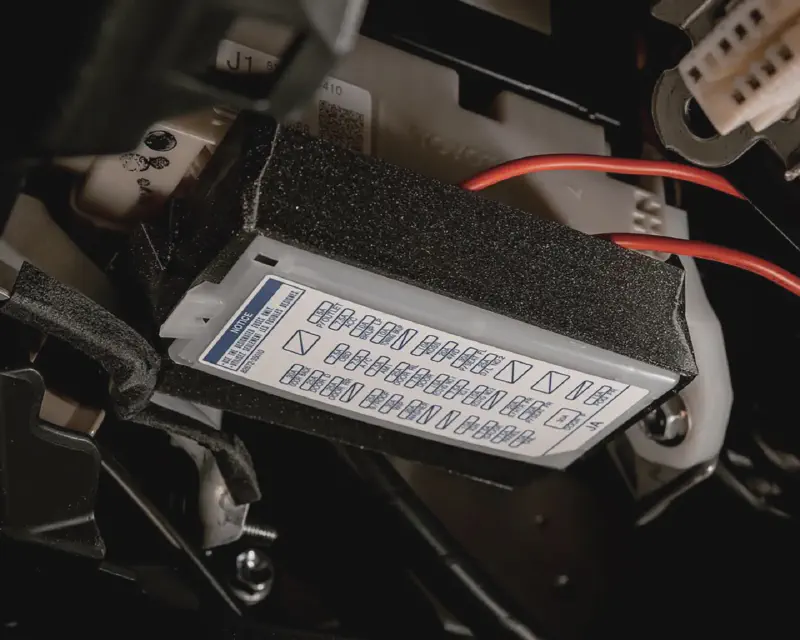

The Extended Fuse Cover accomodates extra room for many 4Runner electrical modification connections

Many of our 4Runners have enough added modifications to make our cabin fuse box a delicious spaghetti bowl of electrical taps, splices, and add-a-fuses.

The resulting blob of wires usually prevents the OEM fuse cover from fitting back on and so it usually gets left off. There are many aftermarket extended fuse covers available but inventor Minh found they really weren’t up to his exacting standards.

While trying to develop an improved version, he tucked away his OEM cover with one of the prototypes. At this moment he realized mounting the OEM cover directly onto the extended cover was the best way to keep track of it and display the relevant fuse diagram.

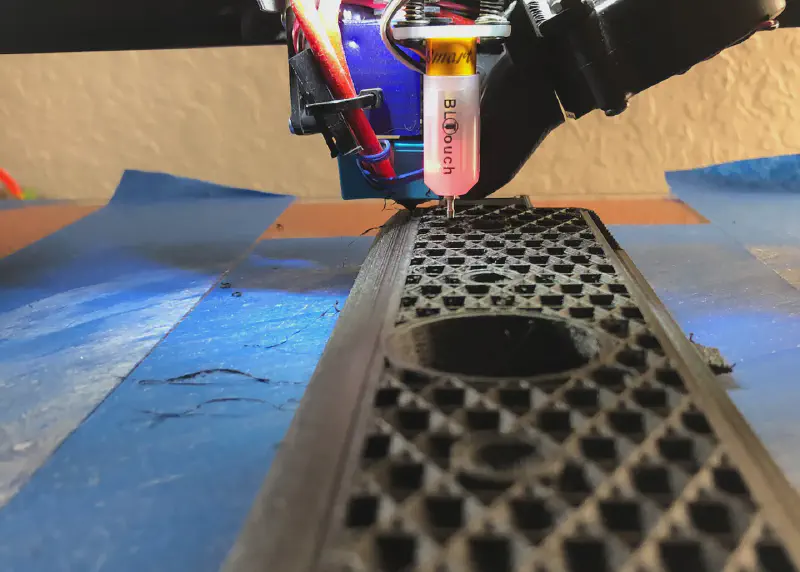

Early challenges with 3D printing

Combining the OEM and extended fuse covers together forced him to redraft his first prototype almost completely. Minh shared that he kind of regrets spending so much time on the first version since it was scrapped entirely anyway. Hindsight is 20/20 and had Minh not spent so much time on that first draft, who knows if he would have had the same realization.

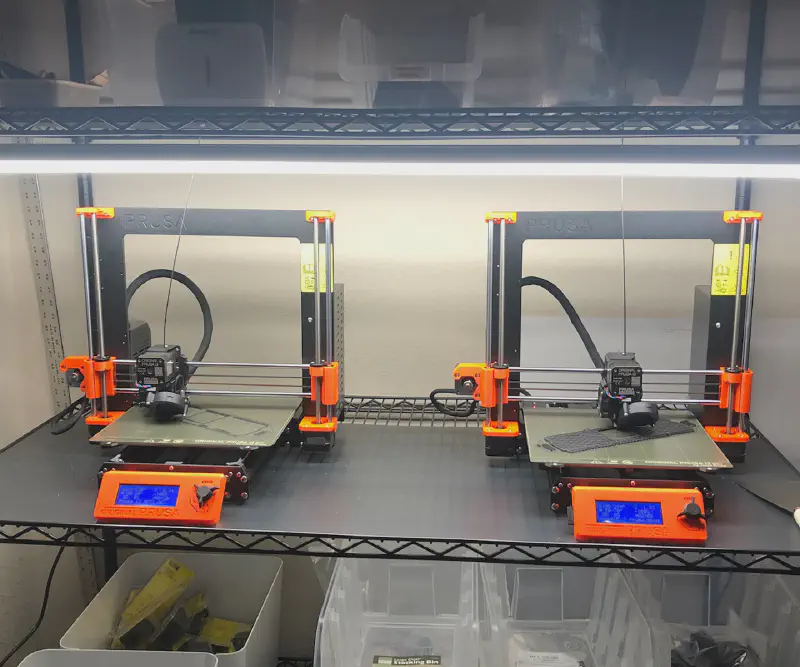

Minh’s 3D printing station

Minh is rather humble and was skeptical if a single invention made him actually an inventor. However, if you keep up with his Instagram or TikTok you can see the level of tinkering, innovation, and prototyping transparency easily puts him in this category.

His discussions about the virtues of PETG plastics over ABS and PLA for rigidity, durability, and heat resistance are both fascinating and educational. It is rare to see someone so open to publicly sharing their design issues and work process while engaging directly in long conversations with strangers.

Perserverance is invaluable in the face of technical challenges

To carry on a theme, Minh was also direct about being resilient and open during the development process. After the major re-work of his first 2010-2019 extended fuse cover prototype, Minh went through a further 56 revisions, 12 of which were major design changes.

Additionally, there were some close to Minh who shared skepticism about spending so much time on something as benign and simple as a fuse cover. Yet, through all of this, he was able to turn a healthy profit. This has only fueled his workshop’s expansion and desire to further develop custom 5th Gen 4Runner products.

3. Wifey Air System by Al

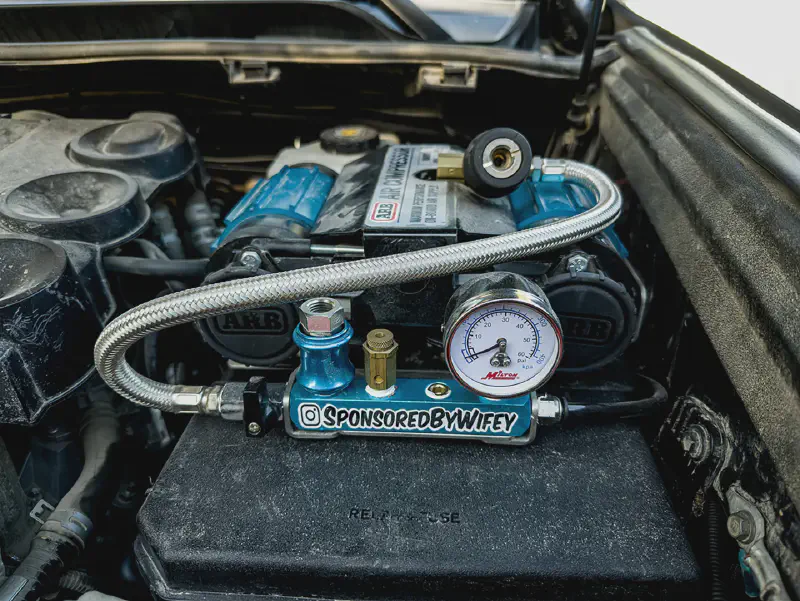

The Wifey Air System

While Al enjoys wheelin’ with his friends almost every weekend, he didn’t particularly enjoy the task of airing up and down. As a result, he bought one of those four-way hoses to do it more efficiently. He shared that his first time using it was also his last.

The whole process of untangling the hoses, laying them out for all four tires only to do the same in reverse once finished seemed like a lot of tedious work. Not to mention all the associated gear taking up a storage spot in your vehicle that had to be easily accessible.

Looking for built-in hose systems lead Al to a lot of dead ends. Eventually, Al came across one company that seemed to share his vision for a hose system. He eagerly emailed them but with no response after a few days, he gave them a call that went unanswered. Al found out that this company went out of business so his ideal hose setup was still unavailable anywhere on the market. The only thing left to do was to make it himself.

The first week was a flurry of online orders for fittings, hoses, and quick connectors. Excited about the potential of sharing a working prototype with his friends on a weekend trip, Al worked a few late nights getting everything assembled and working.

The result was a solid first prototype that even lasted until he later sold his 4Runner. The inaugural Wifey Air System had everyone gathering around his 4Runner to see it working.

The initial Wifey Air System setup

Al wasn’t in it for the money. He had just built an awesome system that was easy to use and tucked neatly away under the vehicle; so why not share it with everyone? He did just that and you can even see a full parts list on some of his older YouTube videos. Even with a full parts list, there were a few people who didn’t have the time or interest in assembling it themselves. Al built those people kits on occasion but his overall order volume wasn’t high.

It wasn’t until a prominent fabrication company reached out and offered to build his built-in air system as a purchasable kit that Al started getting serious. At that time, he had noticed a few exact clones of his air system being offered on the market. If people wanted to pay for a pre-made kit with his publicly available parts list, then why couldn’t he make some money too?

A later iteration of the Wifey Air System

The evolution of the Wifey Air System from open source to being offered as a product is a testament to consumer demand. There is a distinct possibility of sharing your secret recipe with the world while still being able to offer a product. The real question is if Al is still sponsored by wifey or if this built-in air system has started to cover the bills.

4. SD Off Road Mount by Derek

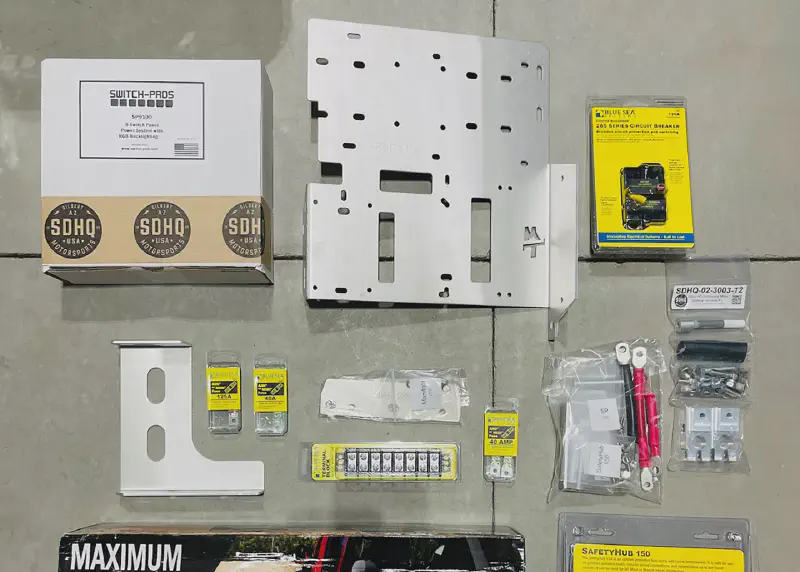

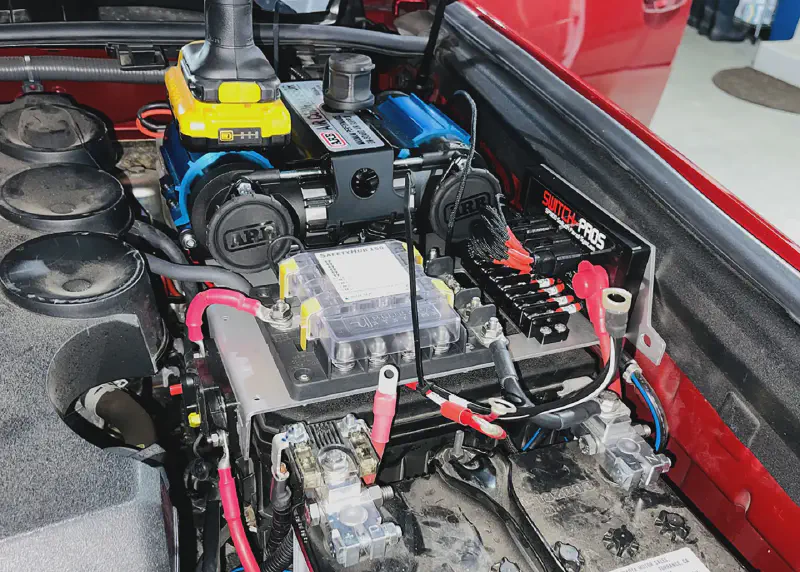

A brilliant aluminum plate to consolidate several systems in your 4Runner’s engine bay

When I was looking to start the foundation of my 4Runner’s electrical modifications last year, there were a ton of options for mounting a solid-state switch in my engine bay.

I was pretty greedy and wanted my onboard air compressor, switches, fuse block, and bus bar to all fit together on the same tray. However, I couldn’t find a product that had that much real estate. Sure, there were many that combined a few of those components together but none I saw that did everything. This is especially true for the Switch Pros’ requirement of being mounted vertically for warranty purposes.

SD Off Road Mount installed and being wired

It took me a while, but I eventually came across the SD Offroad Mount. Operating directly out of his Instagram page rather than a website is a bit unorthodox. However, it makes sense for a single man with a garage workshop.

In a conversation with Derek in late 2021, he acknowledged being just one guy in a huge off-roading world with a successful product because people believed in what they saw.

5. Anytime Backup Camera by Brian

Anytime Backup Camera: Check Price Our last innovator highlight is a product you would think could come stock directly from Toyota. The Anytime Backup and Front Camera system (updated version) let you view your OEM backup camera whenever you want and adds a front camera to boot.

Brian has broken the fascist tyranny of the reverse gear over backup cameras everywhere! Using this camera during off-roading can prove invaluable for checking approach angles or how close that sharp rock is getting.

The original motivation for putting together this wiring kit stemmed from Brian’s goal of not messing with the stock wiring of his newly purchased 4Runner. Why modify the core of your vehicle’s electrical system when with a few clicks you can get enough wiring to shame a 1999 Radio Shack?

Final Thoughts

Custom 5th Gen 4Runner products play a large role in the mods world. Not every large company can allocate the time and money for what some would consider niche products. This is where inventors fill the void for the community’s needs.

Some of the folks listed in this article had engineering backgrounds; one even had a Ph.D. However, as shared at the beginning of this article, the amount of information available to us is almost boundless. If you have an idea for something you don’t know how to build, the internet can teach you so many things!

Everyone listed here has a day job and did most of their learning in their spare time. You don’t need to spend hours every day either, take your time, and that knowledge will compound. There isn’t really anything that you couldn’t eventually master or at the very least become competent with.

While there might be really niche fields that don’t have thousands of video tutorials, you can be assured that there is some content out there, somewhere. If you come across a field you can’t find much on, drop me a line and we can look together!